Electroluminescent Materials

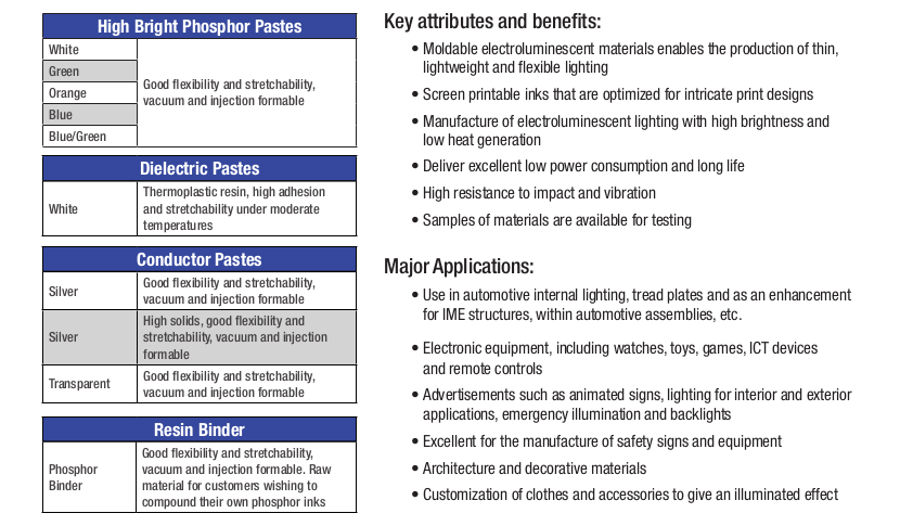

Servilan through Sun Chemical Advanced Materials offers a range of Electroluminescent Materials that offer good flexibility and can be molded to shape by vacuum forming, also they can be incorporated into IME structures.

Sun Chemical provides a full range of phosphor pastes that are color controlled to CIE 1931 using x, y parameters. Our line of dielectric pastes can help deliver the high capacitance that is needed. Our electroluminescent materials provide outstanding adhesion to ITO and flexible substrates, to deliver excellent chemical, environmental and abrasion resistance to ensure the production of durable, long-life lighting.

Recuerda que te asesoramos y buscamos el producto que necesites sin ningún compromiso.

Etiquetas: electroluminiscencia, Sun Chemical, tintas electroluminiscentes